Products

DRY BREAK COUPLING

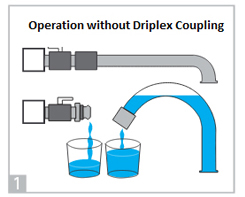

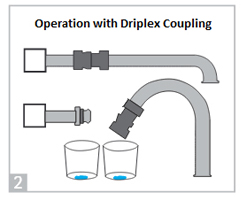

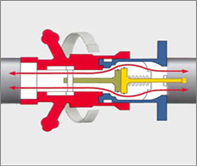

A Dry Break or Dry Disconnect Coupling is an internationally preferred hose connection device which provides an automatic mechanism to seal off both the hose and the fixed pipe end when the hose is disconnected.

Dry Disconnect coupling is a safer, environmentally responsible and technologically advanced replacement for Quick Release and Camlock Coupling.

How does a Dry Break Coupling work?

Why Use A Dry Break Coupling?

Technical Details

Sizes : 1" (DN19 - DN32) to 6" (DN150).

Materials : Aluminium, gunmetal and stainless steel 316L, other on request.

Seals : FKM (Viton®), NBR (Nitrile), EPDM, Chemraz®, Kalrez®. Other materials on request.

Working pressure: 10-25 bar

Test pressure : Working pressure +50%

Safety factor : 5:1

End connections: BSP- and NPT-threads. DIN-, ASA-, TW- and TTMA-flanges (available for both coupler

and adaptor). Other threads and flanges on request.

Compatibility: NATO STANAG 3756.

Materials : Aluminium, gunmetal and stainless steel 316L, other on request.

Seals : FKM (Viton®), NBR (Nitrile), EPDM, Chemraz®, Kalrez®. Other materials on request.

Working pressure: 10-25 bar

Test pressure : Working pressure +50%

Safety factor : 5:1

End connections: BSP- and NPT-threads. DIN-, ASA-, TW- and TTMA-flanges (available for both coupler

and adaptor). Other threads and flanges on request.

Compatibility: NATO STANAG 3756.

Viton® and Kalrez® is registered trademarks of DuPont Performance Elastomers. Chemraz® is a registered trademark of Green-Tweed

How does a Dry Break Coupling work?

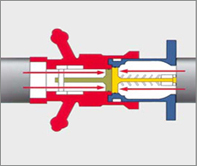

- This coupling simply works by turning the hose unit 15-degree clockwise locking the units together.

- The valves are still closed and are not opened until a further rotation has been performed and then the product flow is guaranteed.

- The rotary action forces the internals of the hose unit forward, opening the tank unit. Once coupled, transfer of product is possible.

- On disconnection both the hose and tank units close automatically and spill free disconnection is achieved

Why Use A Dry Break Coupling?

Easier To Operate

- Integrated 360 degree swivel.

- Simple single action operation – only handles to turn.

- Automated valve design

- Disconnection & connection possible under pressure.

Higher Safety Standards – 'No Spill' Technology

- Mechanical interlock prevents accidental openings.

- Casting in SS 316 to ensure maximum strength.

- Automated valve design reduces the chances of human errors.

- Viton seals are a standard feature to increase life and safety of the product.

Better Flow

- Smooth bore and simple configuration of coupling results in minimal pressure drop.

- Ideal for high viscosity fluid transfers.