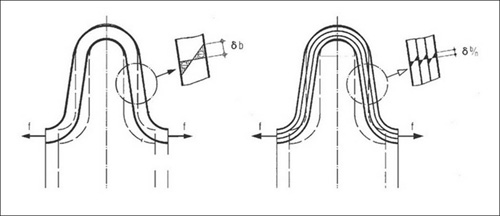

MULTIPLY EXPANSION JOINTS

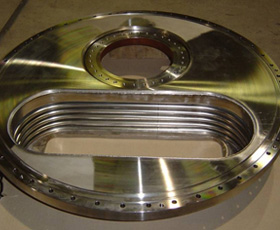

WELDLESS CORNERED RECTANGULAR MULTIPLY EXPANSION JOINTS

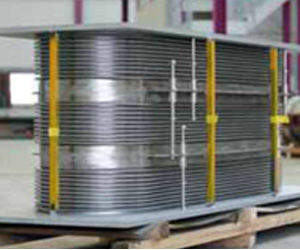

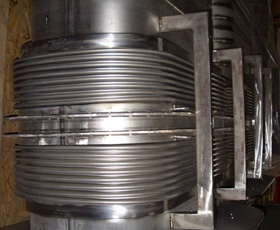

LARGE DIAMETERS BELLOWS

FABRIC EXPANSION JOINTS

JRE represents Kompaflex; the leading specialized Metallic Bellows manufacturer in the world.

Kompaflex is a Swiss company specialised in the design and production of metallic and fabric expansion joints for critical applications. Since its creation in 1981, Kompaflex ag has become a key partner among large equipment manufacturers and end users in the development of innovative and unique solutions. Due to the increasing demand for metallic expansion joints, Kompaflex sro was founded in 1995. Kompaflex DMM is the third unit of the group, born from a joint-venture with kompaflex ag. This subsidiary manufacture a range of fabric expansion joints, metallic expansion joints. There are in total more than 120 persons contributing to the production of expansion joints, across a combined manufacturing area of 10 acres.

Materials Used in Kompaflex Bellows :

1) Stainless Steel Metals

2) Carbon Metals

3) Nickel, Titanum, Inconel, Hastellow, Monel and other available on request

Size range:

1) DN 50 to DN 12000

Petrochemical and Oil-Gas Bellows

![]()

As the leading bellows manufacturer, Kompaflex ag’s approach is to provide a reliable and satisfactory customer service. Our innovative approach and expertise enable us to manufacture customised expansion joints, thus meeting our customers’ most stringent needs whatever the given pressure, temperature and media.

Kompaflex ag is one of the rare bellows manufacturers to be capable of offering unique designs.

1) Customised solutions to answer the customer's specifications2) Circular, oval and elliptical, conical, rectangular

3) Large diameters

4) Ultra-high vacuum and high pressure

5) High performance materials

Kompaflex ag masters the production of multiply expansion joints.

The high flexibility and high pressure stability are two essential but diametrically opposed requirements of an expansion joint. However a multiply expansion joint combines both by breaking up the single wall into a number of neutral axes.

They feature the following advantages :1) Reduced Stresses

2) A Better Flexibility

3) A Compact Construction

4) A Leak Control Device

5) A Higher Number of Cycles

6) Lower Spring Rates

7) A Higher lifetime

When the use of rectangular expansion joints is necessary, welded corners are usually produced. The highest mechanical stresses are concentrated in the corners and weldings become the weakest links of the whole structure.

Our expansion joints are manufactured in such a way that no welding appears on the corners, only one appears on the longitudinal side.

Kompaflex is the only manufacturer able to master such technique.

1) Multiply construction2) Easier welding inspection

3) No welding seams in the critical corner area

3) Higher flexibility and higher movements of bellows

3) Longer life of expansion joints

A number of manufacturers offer large scale equipment’s to increase the production and yields. Kompaflex has understood this constant search for performance by manufacturing metallic expansion joints with up to 12 meter diameter.

Large expansion joints above 6 meter diameter are often best being manufactured directly on site for logistical reasons.

Through its subsidiary, Kompaflex manufactures Technical Fabric Compensators (TFC). Their main advantage is their ability to absorb any multidimensional movements of the adjoining pipes due to high flexibility and relatively small counteraction force.

This flexibility also allows to build simple pipeline tracks and the latter quality enables development of economical technical solutions for the fixed points of pipeline constructions