Products

STAINLESS STEEL HOSES

Stainless Steel Corrugated Hoses

Hose Standard : BS 6501

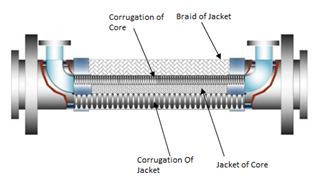

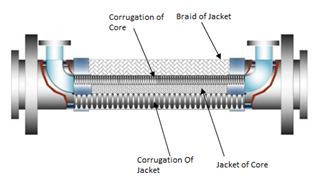

Construction : Flexible tubing, single thickwall corrugation, without packing, annular corugation hydraulically formed.

Profile : Close pitch corrugation

Size Range : 6 mm upto 350 mm

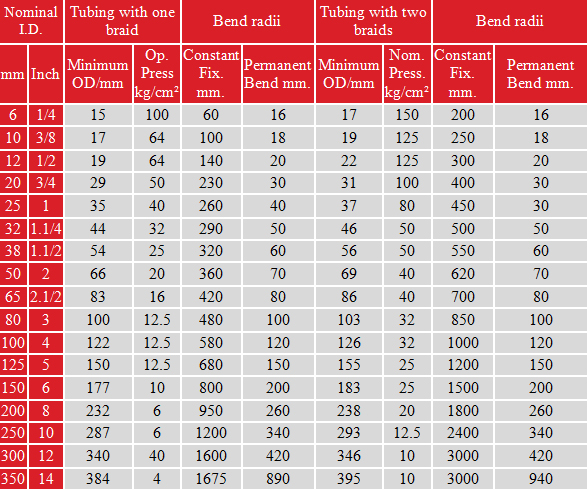

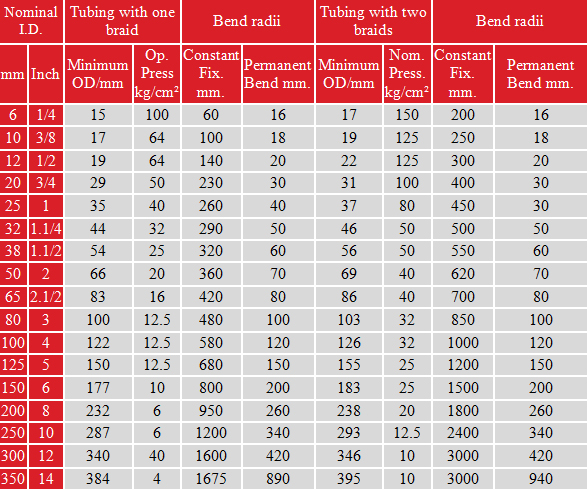

Pressure Range : Upto 150 kg/cm³ or higher against specific requirement. The pressure value indicated in the table (technical data) is fuction of the diameter, of the temperature, of the number of braids, of the material used and of the type of application.

Temperature: Upto 800°C

Core Material : 321/304/316/316L * Monel/Bronze.

Braid Material : SS 304/SS 321

End Fittings : Tig welded, mechanical, soldered, silver brazed.

Application : Due to their outstanding characteristics, JRE/S.S. 1W & JRE/S.S. 2W hose assemblies are suitable for a wide variety of applications. Wherever flexible pipe is necessary they may be applied.

Construction : Flexible tubing, single thickwall corrugation, without packing, annular corugation hydraulically formed.

Profile : Close pitch corrugation

Size Range : 6 mm upto 350 mm

Pressure Range : Upto 150 kg/cm³ or higher against specific requirement. The pressure value indicated in the table (technical data) is fuction of the diameter, of the temperature, of the number of braids, of the material used and of the type of application.

Temperature: Upto 800°C

Core Material : 321/304/316/316L * Monel/Bronze.

Braid Material : SS 304/SS 321

End Fittings : Tig welded, mechanical, soldered, silver brazed.

Application : Due to their outstanding characteristics, JRE/S.S. 1W & JRE/S.S. 2W hose assemblies are suitable for a wide variety of applications. Wherever flexible pipe is necessary they may be applied.

Special Hoses available on request:

- Extra High Pressure

- Smooth Bore

- Jacketed hose Assembly

Application:

The main application of Stainless Steel Corrugated hose assemblies is where synthetic rubber hoses & plastic hoses do not work well i.e. for hot water, steam, condensate, gas, corrosive liquids, acids, ammonia, carbonic & tartaric acids, tannic acid, nitric acid, sulphuric acid, dye stuff, mercury etc.

In refineries:

To convey oils; gasoline, LPG, benzol, petrol, alcohol, LSHS, liquid gases, steam, and other derivates

In Chemical Industry:

For the changing, mixing & Conveyerlines

In power Plants:

For cooling lines etc.

In Reactor Installation:

For cooling lines etc.

In steel Plants:

For supply of air and oxygen and for blast furnaces.

And everywhere:

Where corrosion and vacuum are major problems.