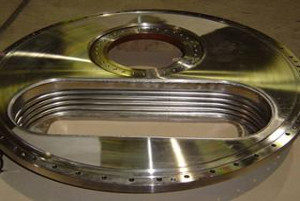

Metal bellows are vessels with elastic properties capable of being compressed by pressure being applied on the outer part of a vessel. These can also get compressed when protracted under vacuum. As soon as the pressure is set free, the bellows go back to their original shape. Metal bellow seals behave in a similar manner.

These are seals that become compressed when under pressure from outside the container or when vacuum is present in the outer atmosphere. They usually have a rubber ring forming the main the component of working. Bellows are applicable in various fields including oil refineries marine engineering, petrochemicals, and offshore platforms.

How to choose the best?

When purchasing metal bellow seals, it is crucial to get the most suitable for your type of application. The good thing is that you can find reputable brands like Kompaflex. These can provide seals customized to fit your individual demands and requirements. But in essence all the seals that you choose ought to be:

- Simple to install

- Resistance to abrasion and corrosion

- Long lasting and durable

- Slip and stick free

- Reliable in dynamic sealing and high static

- Withstanding to high pressure and temperature ranges

The materials metal bellow seals are made of determines their quality. Some of the best are manufactured using carbon and other quality materials. It gives them the features to withstand high pressures and temperatures. So, when buying bellow seals, always think about the materials they are made of. It might help you get the best for your application. Seals that come with a bellow are better since they eliminate the need to use springs.

For efficient performance, get seals of high tensile strength. You also have to pick those that will give you an easy time to install. If you have any particular requirements, find out whether your supplier can engineer and customize them accordingly. ISO certified seals will never disappoint no matter the application so have this in mind too.

Metal bellows seals using O-rings to seal leakages are an excellent choice. But it is useful to look at the available options. It might help weigh the pros and cons of each before coming up with a final decision. Discover information from a trusted manufacturer to get you the best seals for your application.

What is the application of bellow seals?

Metal bellow seals are mainly applied to eliminate contamination of liquids from external environment this is more pronounced in heat transfer fluids. They are made to be of high resistance to abrasion and to be durable when serving their functions.

The seals help in removing elastomers in chemical processing industries. The dangerous effects involved in chemical industries make the metal bellow seals perfect in preventing accidents. They high-temperature resistances to make them do this function well. Bellow Seals can act as stoppers for hot liquids. This is noticed polymers, cryogenic applications, and resins.

Other applications where bellow seals are applied include pigmenting, textile industry, and dying industries. In the food industry, they are used in dairy industries to work on cream, milk and processed milk containers. Further still, bellows are applicable in beverage industries for beer, fruit juices, and fruit syrups. They are even used in water treatment plants and waterproofing industry.

Leave a Reply