Hoses are hollow tubes that are flexible. Hoses are used for carrying fluids between two locations. They are also called sometimes pipes, but a hose is being flexible while a pipe is just a rigid tube. A hose usually has a cylindrical shape. Hose design is aims to achieve a combination of performance and application. Common factors in hose design are length, weight, size, chemical compatibility and pressure rating.

Hoses can be built from a combination of various materials. The most used materials for Product Design Prototypes are PVC, polyethylene, polyurethane, nylon and natural or synthetic rubbers. The materials are selected for various hose applications based on the pressure rating and environment needed. More recently, hoses started to be made of special grades of polyethylene called XLPE and UHMWPE. Other materials used to build hose include stainless steel, Teflon (PTFE), as well as other metals.

Hoses can feature reinforcement structures made of steel cord or fibers in order to ensure a better pressure resistance. Among the reinforcement methods that are commonly used are included wrapping of fabric plies, knitting, spiraling and braiding. The reinforcement has the role to increase the stiffness as well as the pressure resistance of the hose. In order to obtain flexibility are used bellows or corrugations. Helical or circumferential reinforcement rings are usually applied in order to maintain these bellowed or corrugated structures under the buildup of internal pressure.

Applications

Some hoses are used to transport air or other gases, while others are used for water and other various liquid environments. Hoses that carry fluids through fluid or air environment, are being typically used with nozzles, flanges, spigots and clamps in order to control the flow of the fluids. Hoses for technical gases include low pressure hoses as well as high pressure ones.

Aspects such as safety factors, required standards, gas flow, electrostatic properties, gas permeation, working temperature, working pressure and type of gas are taken into consideration when choosing the appropriate hose for technical gas. For instance, a nitrogen hose is a high pressure hose used for carrying nitrogen gas. A nitrogen hose is usually made of a stainless steel double braid outer, with PTFE liner.

Specific applications for hoses include:

- A fire hose is used to carry water to a fire site.

- A garden hose can transport water to a sprinkler or directly water a lawn or garden.

- An air hose carry air from an air tank or surface compressor in underwater diving applications.

- A Tough Hose can be found in drip agricultural irrigation applications to water crops.

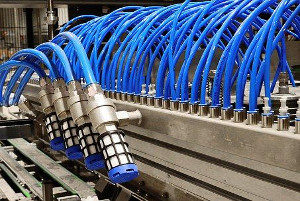

- Industrial hoses are used for operating worktable tools or flexible machinery, including staplers, grinders, pneumatic screw drivers and other.

- Hoses can also be found in air brake systems, including railroad cars, locomotives, and trucks.

- Hoses are found in vacuum brake systems.

- Plastic and metal hoses in building services are used to transport water.

- Air duct hoses are found in air conditioning systems.

- Automotive hoses move fluids for use in hydraulics, lubrication and cooling systems.

- Tube hoses are found in medicine and chemistry applications.

- Fuel hoses are found in fuel carrying applications.

Leave a Reply